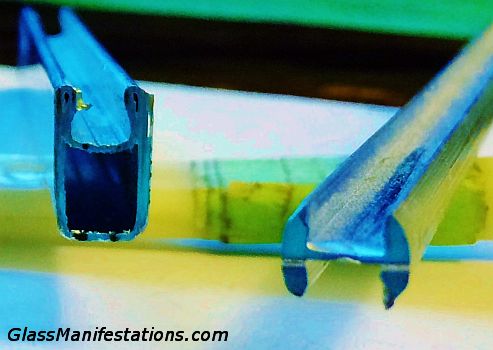

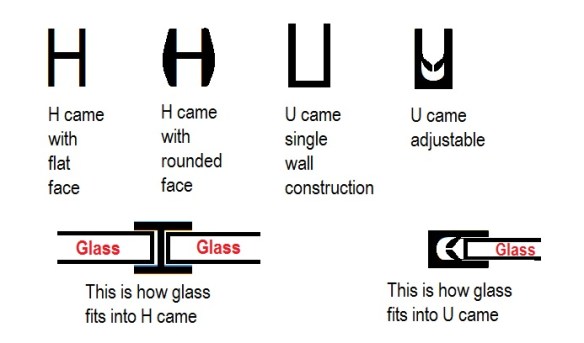

It is weeks in the making. First the design is conceived, drawn and copied for a pattern to attach to the worktable. Glass is selected by color, texture, opacity… or sometimes simply availability and affordability. The glass is cut, ground and sized until each piece fits perfectly into the pattern. Individual pieces are wrapped with leading, lead joints soldered together, then putty is worked under the lead for stability and waterproofing. Cleaning is done in place with a bristle brush and whiting powder. Then, the wait.

The putty takes three days to set. Twice daily the artisan cleans off any putty that seeps from beneath the lead. She notices where she applied too much solder. Or too little. She guiltily surveys a piece she had cut too small but used anyway, knowing she could fudge with lead or putty to hide the gap. She second-guesses her glass choices. Will the colors compliment or contrast as she intended? Will the nuances of the design come across as planned?

When the putty is set, it’s time. The artisan lifts the stained glass panel, wipes it clean and rests it gently on a windowsill. She backs away and for the first time gazes upon the completed work. The critical eye judges workmanship, mercilessly and exacting. The artistic eye must wait ‘til the critic quiets. And lastly, the cautious heart will weigh in on the worthiness of the piece. The verdict? We’ll have to wait and see.

patience takes patience

minutes take sixty seconds

waiting takes its time

“Hammer Shattering Glass Shattering Hammer” stained glass panel by Maggie C.